Project Update: 32 - A New Year update

Hello Vaulters, and happy new year! This update shares progress since the last update and looks forward into the new year. No action is required.

PAX Unplugged

The entire Vault team made the trek out to PAX Unplugged and we were delighted to meet so many current and new backers. It was a delight to chat with folks and, when they enthused over the art, then turn to Marshall and reveal that he was (and is!) the artist.

For real, it’s just a huge shot in the arm of good vibes to talk directly with the people we’re building Vault for. Players. New DMs. Veteran DMs. Anybody who wants to have minis on the table, but doesn’t want to spend a million years painting, a million dollars collecting, and a million cubic feet of space storing. Not to mention a million hours searching for the right mini! Buoyed with enthusiasm and dry-throated & ravenous from singing the Vault’s praises all day, the team headed out to a well-named and well-regarded Philadelphia pub.

There was much rejoicing, and much planning–because not only had we met with oodles of Vaulters, we had also met with the many manufacturing reps that come to shows like PAX. This trip was about generating awareness and pre-orders but it was also about face-to-face time with the folks responsible for making and assembling the Vault, and future Vault expansions.

We’re not nearly ready to share those future plans but we do have updates on the ongoing pre-production process.

Pre-Production Update

Last month we talked about the back-and-forth about the plastic connector elements, and the design of the doors. Those elements are confirmed locked in and ready to go. However, some standee and terrain elements we thought had been accepted as final were kicked back to us once they got down to the engineers responsible for building the dies used to score each sheet. This was frustrating because those particular files had been handed over many months ago, and the issues were only being raised now.

Tinker Chris labored over the holidays to correspond with our manufacturer & their technician team, and then reconfigured and rebuilt the files they had trouble with. As of this point in time they have not responded with any further issues and we are being told that we should be receiving electronic artwork proofs soon.

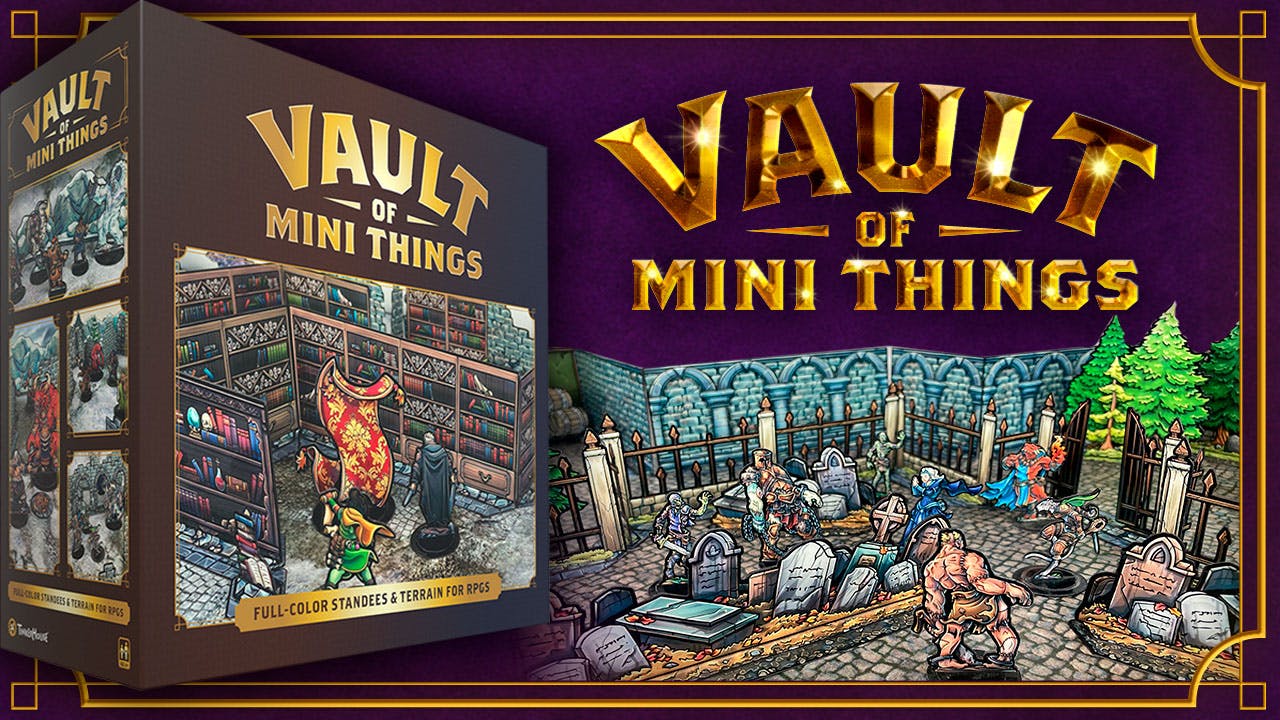

So what remains? The box exterior artwork. The box exterior has been low-priority considering the mass of components that go into it. We’ve created all of the artwork for the box with placeholders for the images that still need to be created. With packaging you end up running into the chicken and egg conundrum, where you would need the product to create the images for the outside of the box. Typically you would wait for manufacturers samples and take pictures of those. In order to speed up this process, we have (as part of our process) created the components in Blender. This has been quite the ordeal over the holidays as some of these components didn’t quite automate with our process so some hand tooling was required. Now that we have the components built we just need to stage and light everything in Blender so that we can constantly output the images that we need. We expect that to take a couple of weeks to do and then we can finalize the artwork and send it to the manufacturer.

We will keep folks updated as we continue to lock down elements. As ever: thank you for your continued support!

Sincerely,

Mike, Chris, Lane, and Marshall

For your edification, here is a video of die cutting: https://youtu.be/mnTD-W5kWBs?t=719

Comments

14